High Efficiency - Economical Noise Enclosures

Sound Attenuation

ELIMINATE COMMON NOISE PROBLEMS WITH SIMPLE, EASY TO CONSTRUCT ENCLOSURES.

Reducing noise at its source is the most desirable approach to noise control. A sheet metal or plywood enclosure lined with an acoustic composite is a cost effective way to solve industrial and OEM noise problems. AcoustiGuard™ Barymat ‘BTMM-14C’ and ‘BV-14C’ are versatile composites that can be incorporated into a wide variety of enclosure applications.

Reducing noise at its source is the most desirable approach to noise control. A sheet metal or plywood enclosure lined with an acoustic composite is a cost effective way to solve industrial and OEM noise problems. AcoustiGuard™ Barymat ‘BTMM-14C’ and ‘BV-14C’ are versatile composites that can be incorporated into a wide variety of enclosure applications.

Unit of Measure

| Items |

/ImgCustom/1006/placeholder_notavailable.gif /ImgCustom/1006/placeholder_notavailable.gif BTMM-14C High Efficiency - Economical Noise Enclosure |

/ImgCustom/1006/placeholder_notavailable.gif /ImgCustom/1006/placeholder_notavailable.gif BV-14C High Efficiency - Economical Noise Enclosure |

||||

| Noise Levels | N/A The use of AcoustiGuard™ composites in enclosures can reduce noise levels anywhere from 20 to 40 dBA. Careful preparation of all openings, seals and joints will eliminate noise leakage paths and maintain maximum performance. | |||||

| Protective Cover | N/A Metallized Mylar Film faces in towards the noise source and protects the absorption layer from contamination. | N/A Perforated Vinyl Cover faces in towards the noise source and protects the absorption layer from contamination. | ||||

| Acoustic Foam | N/A Absorbs noise and prevents it from reflecting out of the enclosure. | |||||

| Barrier Layer | N/A Provides transmission loss, keeping the sound within the enclosure. | |||||

| Foam Decoupler | N/A Enhances the performance of the barrier - glued directly to the inside of the enclosure. | |||||

| Performance Data |

N/A

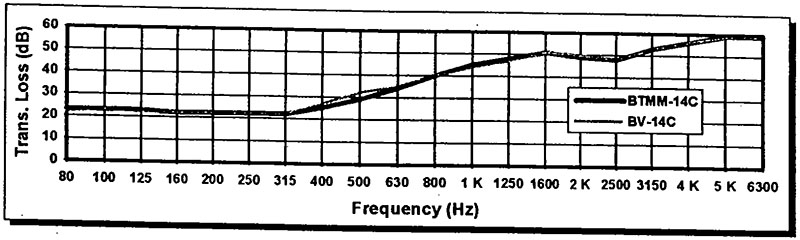

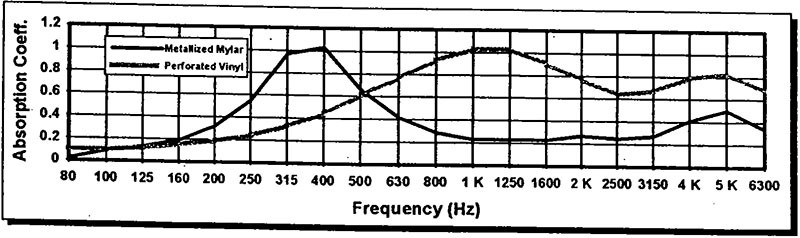

In addition to environmental conditions, individual application requirements will determine choice of composite. These transmission loss and absorption performance charts can be used to make the appropriate selection.

|

|||||

| Thickness | N/A Approx. 1.25 in. - Overall Composite Thickness. | |||||

| Standard Dimensions | N/A Sheets - 54" X 72" (27 sq. ft.) | |||||

| Composite Weight | N/A 1.8 lb./sq.ft. | N/A 1.9 lb./sq.ft. | ||||

| Flammability | N/A MVSS 302-Passes | |||||

| Foam Density | N/A ASTM D 3574-86 — 1.8 - 2.2 lb./ cu.ft. | |||||

| Thermal Conductivity of Foam at 75°F (24°C) | N/A ASTM C 518 — 0.27 Btu. in. / hr. ft.² ºF | |||||

| Installation Recommendations |

N/A

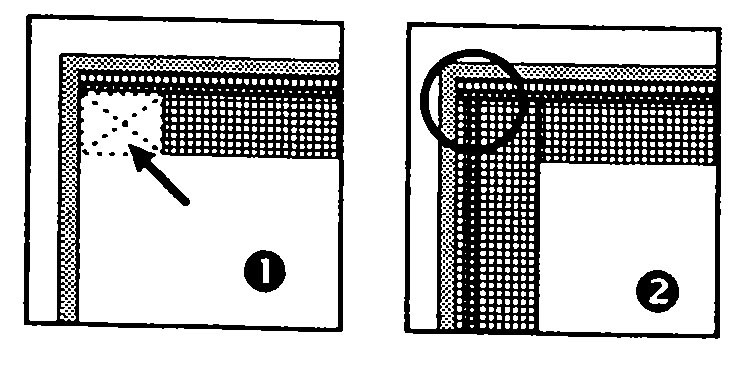

Composite material is glued directly to the entire interior surface of the enclosure. Sheet metal should be degreased and plywood must be primed for best adhesion. To maintain an unbroken barrier layer, care must be taken when fitting material into corners at the horizontal and vertical edges of the enclosure structure.

|

|||||

|

|

||||||