Metallized mylar facing provides high contamination resistance and light reflectivity. It is suitable for very dirty, wet or oily environments and can be exposed to direct spray.

Specifications

Noise Levels |

N/A The use of AcoustiGuard™ composites in enclosures can reduce noise levels anywhere from 20 to 40 dBA. Careful preparation of all openings, seals and joints will eliminate noise leakage paths and maintain maximum performance. |

Protective Cover |

N/A Metallized Mylar Film faces in towards the noise source and protects the absorption layer from contamination. |

Acoustic Foam |

N/A Absorbs noise and prevents it from reflecting out of the enclosure. |

Barrier Layer |

N/A Provides transmission loss, keeping the sound within the enclosure. |

Foam Decoupler |

N/A Enhances the performance of the barrier - glued directly to the inside of the enclosure. |

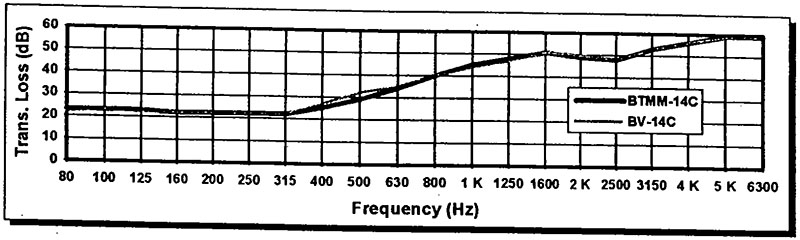

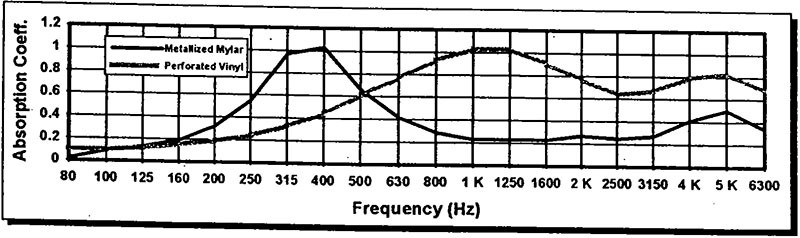

Performance Data

|

N/A

|

|||||

Material Specifications

Thickness |

N/A Approx. 1.25 in. - Overall Composite Thickness. |

Standard Dimensions |

N/A Sheets - 54" X 72" (27 sq. ft.) |

Composite Weight |

N/A 1.8 lb./sq.ft. |

Flammability |

N/A MVSS 302-Passes |

Foam Density |

N/A ASTM D 3574-86 — 1.8 - 2.2 lb./ cu.ft. |

Thermal Conductivity of Foam at 75°F (24°C) |

N/A ASTM C 518 — 0.27 Btu. in. / hr. ft.² ºF |

Installation Recommendations

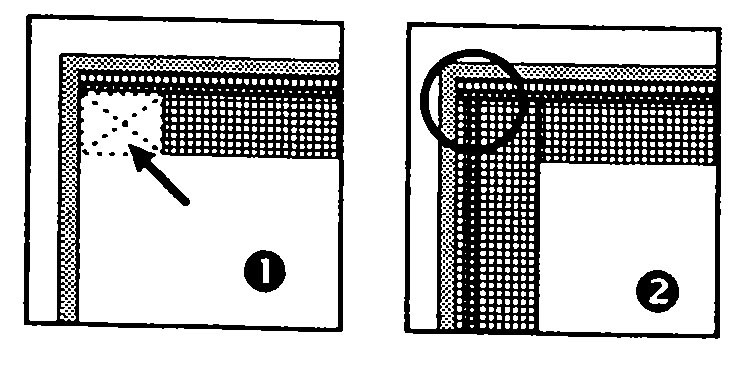

|

N/A

Composite material is glued directly to the entire interior surface of the enclosure. Sheet metal should be degreased and plywood must be primed for best adhesion. To maintain an unbroken barrier layer, care must be taken when fitting material into corners at the horizontal and vertical edges of the enclosure structure.

|

|||